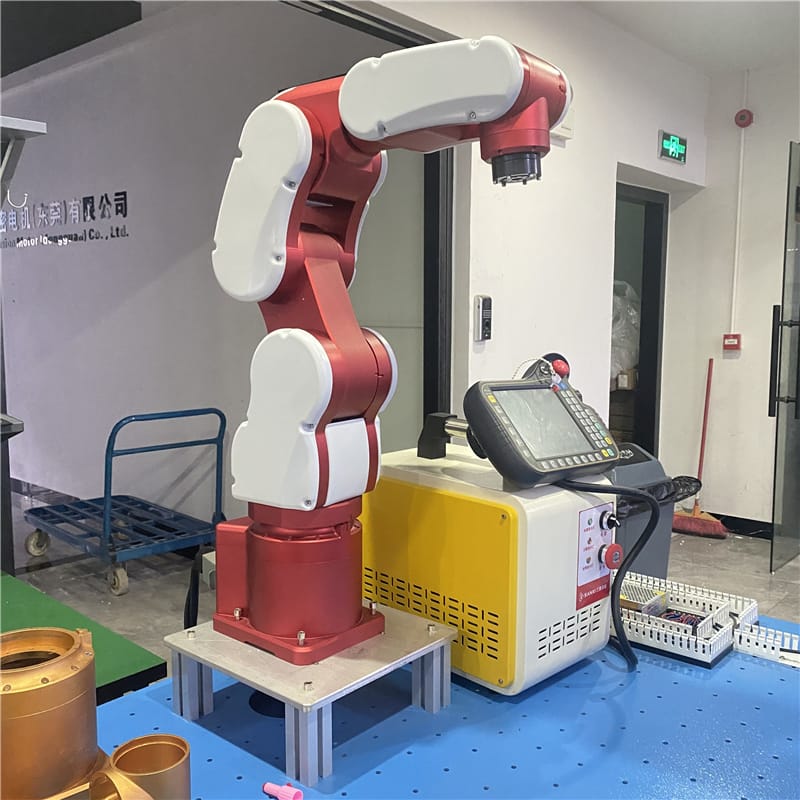

Professional Design Automation Robotic Packaging - Stable 4 Axis Palletizing Industrial Robot Arm For Loading And Unloading – Newker

Professional Design Automation Robotic Packaging - Stable 4 Axis Palletizing Industrial Robot Arm For Loading And Unloading – Newker Detail:

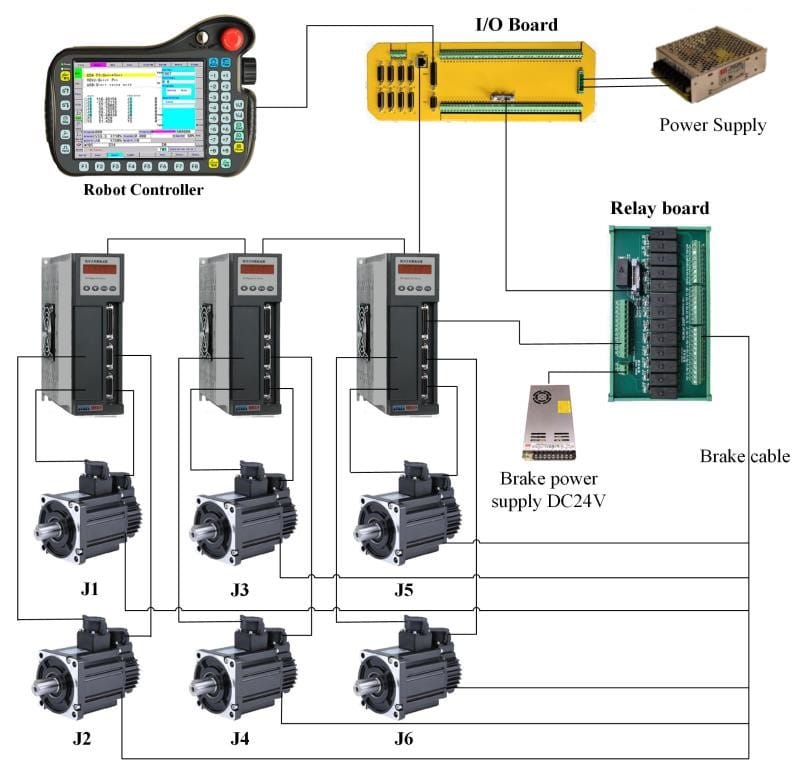

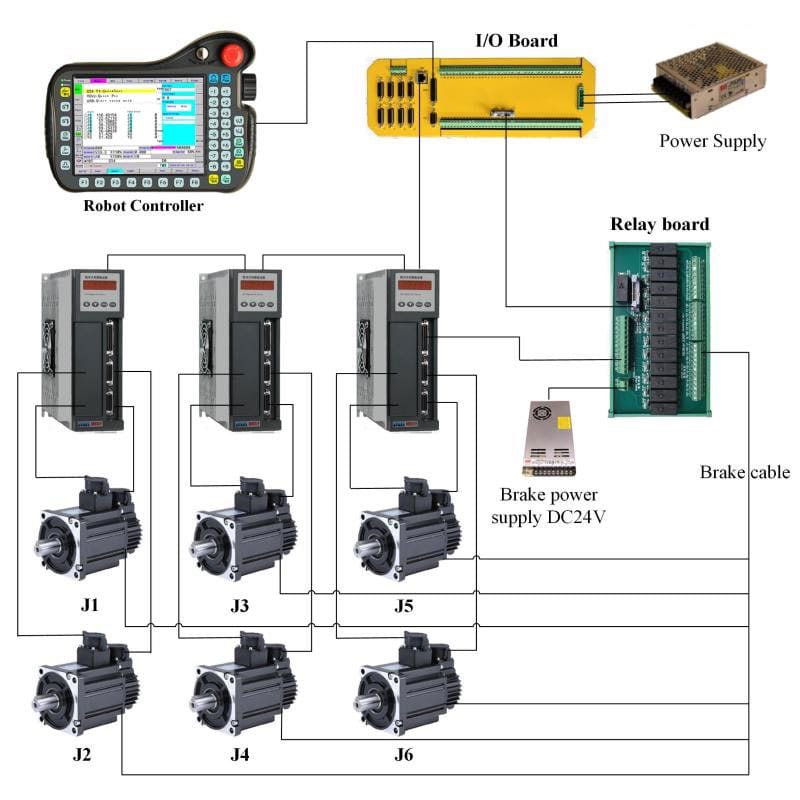

Specification

Axis:4

Max payload:20kg

Repeated location:±0.08mm

Power capacity:3.8kw

Usage environment:0℃-45℃

Installation:ground

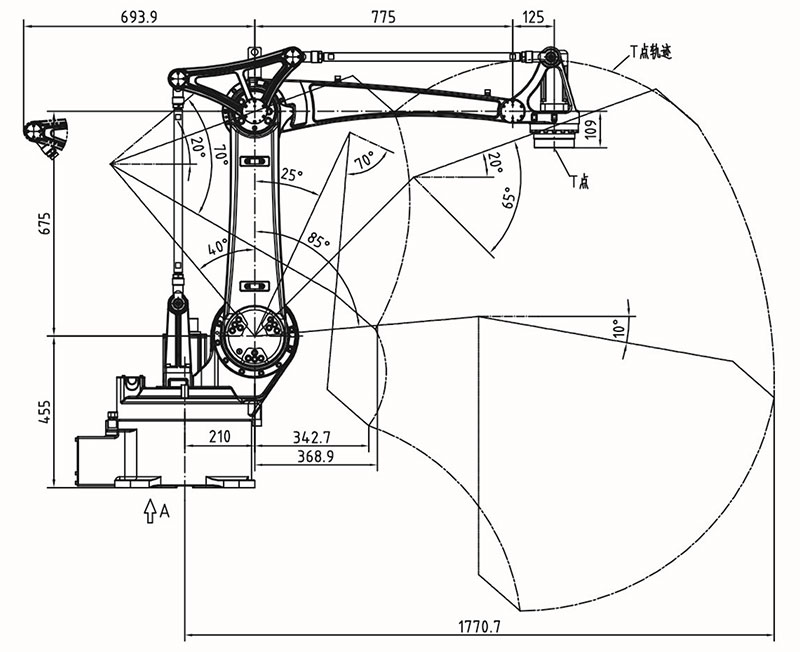

Working range: J1:±170°

J2:-40°~+85°

J3:+20° ~-90°

J4:±360°

Max speed: J1:150°/s

J2:149°/s

J3:225°/s

J4:297.5°/s

working range:

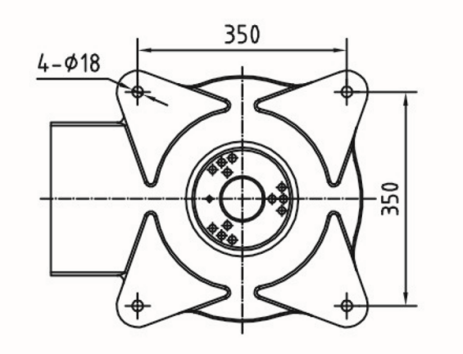

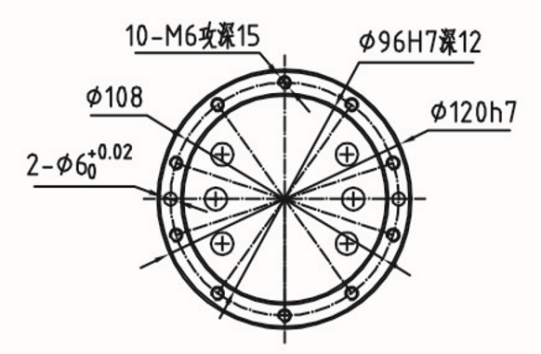

base installation:

base installation:

Machinery Test Report:Provided

Warranty of core components:2 Years

Brand Name:NEWKer

Warranty:2 Years

Type:4 axis robot arm

Product Features

• Just a few hours of installing, teaching, debug-ging, the robot can be quickly put into daily production.

• The design is highly compact, flexible installa-tion with ground or inverse position.

• Large workspace, fast running speed, high repeat positioning accuracy, suitable for welding, spraying, loading and unloading handling, sorting, assembly and other wide range of applica tions• Application Field:

Dairy, beverage, food, beer, petrochemical and pharmaceutical production line handling, disassebly, placement, and other aspects of logistics industry;

loading and unloading etc; especially the mass prduction line of loading goods into boxes, bags, and other high volume production lines.

Advantages

High speed, high efficiency, labor saving, small space occupation, easy operation, flexible, low energy consumption.

The difference between a 4-axis robot arm and a 6-axis robot arm

•A 4-axis robotic arm is more stable than a 6-axis robotic arm.

•The procurement cost of a 6-axis articulated robot will be higher than that of a 4-axis robot.

•The 4-axis robot has a fast response speed, and the 6-axis requires more data to be processed by the controller than the 4-axis, so the response speed is not better than that of the 4-axis.

•The difficulty of use is different. The 6-axis robot operating system will be advanced, involving more parameters, more factors to be considered, and higher requirements for the operator’s requirements and care.

•The 4-axis robot has higher precision, and each joint is engaged with each other. After the system laser compensation, there will be a certain repeatability error. The more the number of axes, the greater the relative repeatability.

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of quality, assistance, effectiveness and growth, we have attained trusts and praises from domestic and worldwide client for Professional Design Automation Robotic Packaging - Stable 4 Axis Palletizing Industrial Robot Arm For Loading And Unloading – Newker , The product will supply to all over the world, such as: Libya, Korea, Moldova, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. people firmly believe we've the whole capacity to provide you happy solutions.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.